Technical Information

Defects and Countermeasures

Nitrile Rubber Packing

| Phenomenon | Conditions | Causes | Countermeasures |

|---|---|---|---|

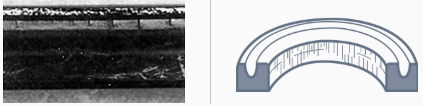

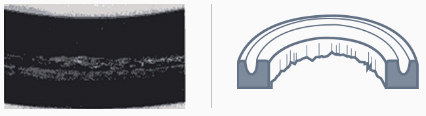

| Degradation |

The entire sealing surface is hardened. Cracks are present on the glossy surface or appear when pressed with a finger. |

Heat generation due to high speed or excessive internal pressure. | For pistons, change to SPG or SPGW. For rods, replace them with a backup ring. |

The entire packing is hardened, causing a significant collapse of the lip. Cracks appear when bent with a finger. |

The oil temperature is high. | Lower the oil temperature or change to heat-resistant material (fluoro rubber). | |

| Effects of oil Incompatibility between oil and rubber material Degradation of oil | Change to rubber material with good oil resistance. Change to a new oil. | ||

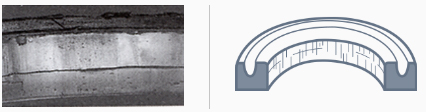

Small cracks occur across the entire packing surface. |

Ozone cracks are caused by leaving the packing exposed to air for an extended period. | Do not unnecessarily open the packaging; keep it sealed and store it in a cool, dark place. | |

| Ozone cracks are caused by leaving the packing mounted on the piston. | Do not leave it mounted on the piston; assemble it into the cylinder promptly. | ||

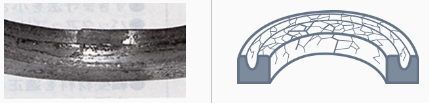

| Swelling |

The entire material has become soft. |

Insufficient formation of the oil film during operation with a small stroke. | Change to rubber material with good oil resistance. |

| Effects of cleaning solution. | Change the cleaning solution. Remove the cleaning solution. | ||

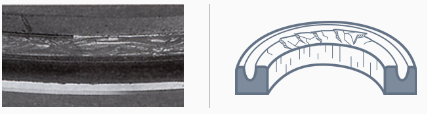

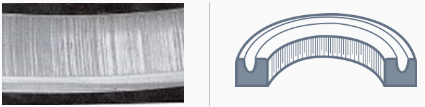

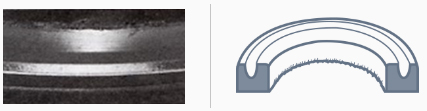

| Wear |

The operating surface is glossy and shows mirror-like wear. |

Insufficient formation of the oil film during operation with a small stroke. | For the piston, change to SPG or SPGW; for the rod, change the back-up ring. |

| Inappropriate surface roughness of the operating surface (surface is too smooth). | Change to the recommended thickness. | ||

The width of the operating section varies continuously along the circumference, with the positions of minimum and maximum width being almost symmetrical. |

Eccentricity between the rod and cylinder bed and between the cylinder and piston bed. | Control assembly eccentricity within the packing tolerance range. | |

A part of the operating lip circumference is severely worn (aligned with the lateral load direction). |

Excessive lateral load causing abnormal wear of the piston and bearing (rod). | Change wearing and bearing materials to those that can withstand the load. | |

| Scratches |

There are partial dent marks on the lip edge. |

Damage caused by external forces during storage, such as hanging on nails, wires, or localized deformation. | Improve storage methods. |

| Insufficient chamfering of the mating part during assembly. | Enlarge the mating chamfer and smooth it to prevent flipping. | ||

| Damage caused by screwdrivers or similar tools during assembly. | Use assembly jigs. | ||

There are scratches on the operating surface. |

Scratches on the mating operating surface. | Perform thorough inspection before assembly. | |

| Perform thorough inspection before assembly. | Chamfer according to specifications and smooth to prevent flipping. | ||

| Embedded foreign particles. | Ensure proper cleaning. | ||

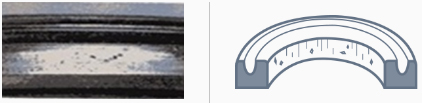

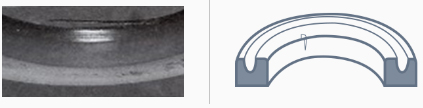

| Indentations |

There are small pit holes on the operating surface. |

Dust or cutting debris embedded due to insufficient cleaning. | Remove foreign particles attached to the equipment. |

| Foreign particles embedded in the oil or deposits formed by oil oxidation. | Replace with new oil. | ||

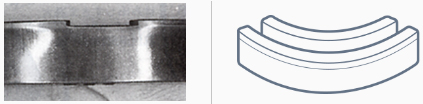

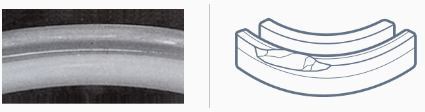

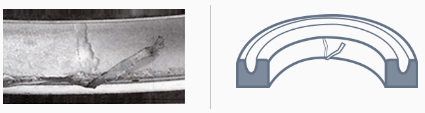

| Breakage |

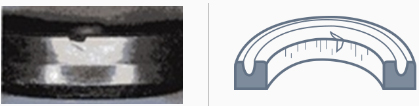

The packing’s operating lip is broken in an arc shape (piston seal). |

Excessive back pressure |

Change to OUHR. Change to SPG (SPGW). |

A crack originated from the packing groove. |

Frequent impulse pressure led to fatigue failure | For the rod, apply a buffer ring. For the piston, change to SPG (SPGW). |

|

| Fracture occurred during operation at low temperatures | Change to packing made of rubber material with good cold resistance. | ||

The operating lip is entirely broken. |

Frequent impulse pressure led to fatigue failure | For the rod, apply a buffer ring. For the piston, change to SPG (SPGW) |

|

| Fracture occurred during operation at low temperatures | Change to packing made of rubber material with good cold resistance. | ||

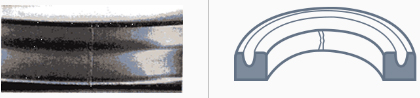

Breakage is found in 1–2 spots around the packing circumference. |

Packing was installed in a twisted state or assembled with improper installation conditions | Improve installation methods and installation tools. | |

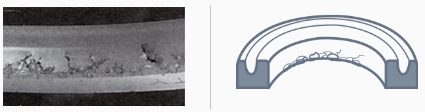

| Burn |

The lip and grooves are locally burned, carbonized, or melted. |

Burn damage caused by adiabatic compression of residual air. | When starting the hydraulic cylinder, fully bleed the air and avoid sudden full-stroke motion. If using a U-packing, fill the pocket area with grease to reduce air accumulation. |

| Extrusion |

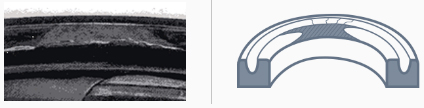

The operating heel is torn. |

Excessive leakage clearance. |

Reduce the gap dimensions. Modify the back-up ring. |

| Severe bearing wear has increased the bearing clearance. | Change the bearing material to an appropriate one. | ||

| Excessive pressure | Modify the back-up ring and reselect the packing. Modify the back-up ring. | ||

The operating heel is torn. |

The groove structure of the equipment is inappropriate. | Adjust the chamfer section. | |

| Gaps formed due to insufficient strength of the retaining plate. | Increase the strength of the retaining plate. | ||

| The back-up ring is inappropriate. |

Adjust the dimensions of the back-up ring. Change the back-up ring material to the correct one. |

||

The packing operating heel and the back-up ring are extruded. |

Excessive leakage clearance. | Reduce the clearance dimensions. | |

| The back-up ring is inappropriate. |

Iron Rubber Packing

| Phenomenon | Conditions | Causes | Countermeasures |

|---|---|---|---|

| Degradation |

The surface is glossy, but it has cracks that appear when pressed with a finger. |

Excessive increase in oil temperature | Lower the oil temperature or change to a heat-resistant material (fluoro rubber). |

| Incompatibility between oil and rubber material | Check oil resistance and change the packing material or hydraulic fluid. | ||

| Oil degradation | Replace with new oil. | ||

The rubber has lost its elasticity and crumbles. |

Excessive increase in oil temperature | Change to a rubber material with good heat and oil resistance. | |

| Incompatibility between oil and rubber material | Check the oil resistance and change the packing material or hydraulic fluid as needed. | ||

| Oil degradation | Replace with new oil. | ||

The operating lip is entirely detached. |

Excessive increase in oil temperature | Change to a rubber material with good heat and oil resistance. | |

| Incompatibility between oil and rubber material. Oil degradation. |

Check the oil resistance and change the packing material or hydraulic fluid as needed. Replace with new oil. | ||

| Wear |

The operating surface is glossy and shows mirror-like wear. |

The operating surface is glossy and shows mirror-like wear. | For pistons, change to SPG. For rods, modify the back up ring. |

| A constant pressure of over 3 MPa is applied. |

For pistons, change to SPG. For rods,

modify the back-up ring. Check the piping resistance and modify the piping layout to achieve a low-pressure configuration. |

||

A part of the operating lip circumference is severely worn (aligned with the lateral load direction). |

Abnormal wear of the wearing ring (piston) and bearing (rod) due to excessive lateral load. | Change the wearing and bearing materials to ones that can withstand the load. | |

The operating surface is worn. |

When operating with a small stroke, the lubrication film is insufficiently formed, resulting in significant heat generation and a thin oil film. | If using a sharp lip, change to an R-lip type. Switch to a combination seal with excellent self-lubricating properties. For rod packing, add a buffer ring. | |

| Scratches |

The tip of the lip is partially torn or dented. |

Damage caused by external force during storage, such as hanging with needles or wires. | Improve storage methods. |

| Enlarge the chamfer of the mating part and make it smooth to prevent inversion. | |||

| Tears or dents caused by needles, screwdrivers, etc., during assembly. | Use assembly jigs. | ||

There are scratches on the operating area. |

Scratches on the mating operating surface. | Perform thorough inspection before assembly. | |

| Enlarge the chamfer of the mating area and make it smooth to prevent inversion. | |||

| Scratches caused by embedded foreign material. | Ensure proper cleaning. | ||

There are scratches on the tip of the lip. |

Scratches caused by the inversion of the chamfered edge of the mating part during assembly | Smooth the mating surface according to the dimension chart. | |

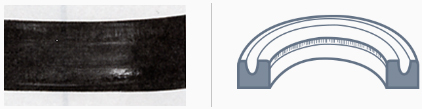

| Breakage |

The operating lip of the packing is extruded in an arc shape or torn (piston seal). |

Excessive back pressure. |

If using iron rubber packing, change to OUIS. Change to a combination seal (SPG, SPGW). |

Cracks originate from the groove of the U-packing. |

Fatigue failure due to frequent shock pressure. |

For rod packing, modify the back-up ring. For piston packing, change to SPG (SPGW). |

|

| Extrusion |

The heel on the operating side is torn. |

Excessive extrusion clearance. |

Reduce the clearance dimensions. Modify the back-up ring. |

| Bearing wear is severe, and the bearing clearance is excessive. | Change the bearing material to an appropriate one. | ||

| Excessive pressure. |

Modify the back-up ring and

reselect the packing. Modify the back-up ring. |

||

There are small indentations from the heel to the lip end on the operating surface, and a thin, film-like extrusion is attached to the heel area. |

Excessive extrusion clearance. | Reduce the clearance dimensions. Modify the back-up ring. | |

| Excessive pressure. | Modify the back-up ring and reselect the packing. Modify the back-up ring. |

||

The heel on the operating side is protruding and deformed, with the entire area discolored red. |

Excessive extrusion clearance. |

Reduce the clearance dimensions. Modify the back-up ring. |

|

| Severe bearing wear and increased bearing clearance. | Change the bearing material to an appropriate one. | ||

| Excessive pressure. | Modify the back-up ring and reselect the packing. Modify the back-up ring. |

||

The outer circumference of the pure PTFE back-up ring is torn, and the packing has extruded and deformed. |

Insufficient strength and wear resistance of the back-up ring. | Change the back-up ring material to 19YF or 80NP. | |

| Burn |

The groove of the U-packing is partially burnt and carbonized. |

Burning caused by adiabatic compression due to residual air. |

Bleed the air thoroughly when starting

the hydraulic cylinder. Do not move rapidly to full stroke. ‘If using U-packing, fill the pocket with grease to minimize air accumulation. |

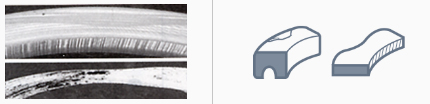

| Deformation |

Deformation and damage in two places on the outer circumference. |

Improper installation in the groove. |

Combination Seals and Seal-related Products

| Phenomenon | Conditions | Causes | Countermeasures |

|---|---|---|---|

| Degradation |

Cracks in the back ring. |

Used under high-temperature conditions. | Replace the back ring with a material with excellent heat resistance. |

| Wear |

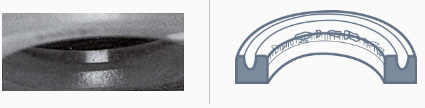

A part of the seal's circumference is severely worn (aligned with the direction of lateral load). |

Eccentricity caused by excessive lateral load and abnormal wear of the wearing or bearing. | Replace the wearing or bearing materials with ones that can withstand lateral loads. |

| The mating sliding surface is partially rough. | Finish the surface roughness uniformly (recommended value: 0.4–3.2 μm Ry). | ||

| Scratches |

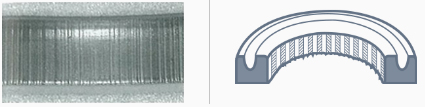

Scratches on the operating surface of the rear front ring. |

Scratches on the mating operating surface. | Perform thorough inspection before assembly. |

| Burrs or flipping of the mating chamfer during assembly. | Chamfer the mating surface according to the specification table, ensuring it is smooth without burrs or flipping. | ||

| Embedded foreign matter (e.g., metal powder). |

Remove foreign matter. Design a contamination seal (KZT) on both sides of the packing. |

||

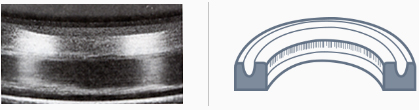

| Extrusion |

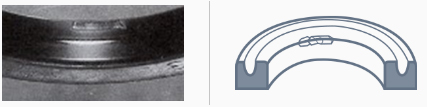

There is a film-like extrusion on the seal operating surface. |

Large leakage clearance. High pressure. |

Reduce the clearance. Change the material to one with higher rigidity. Use SPGW with a back-up ring attached. |

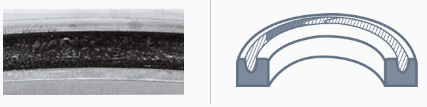

| Indentation (foreign matter embedded) |

Foreign matter is embedded in the seal and back-up ring. |

Foreign matter in the oil and piping system. | Ensure thorough cleaning. Design a contamination seal (KZT) on both sides of the packing. |

| Metal particles are generated due to scraping between the piston and cylinder. | Change the materials of the wearing and bearing to ones that can withstand lateral load. | ||

| Extrusion (back-up ring) |

The back-up ring is extruded. |

Large leakage clearance. High pressure. |

Reduce the clearance. Change the material to one with higher rigidity. Use SPGW with a back-up ring attached. |

| Burn |

One side of the wearing is carbonized. |

Burning caused by adiabatic compression due to residual air. |

Reduce the clearance. Change the material to one with higher rigidity. Use SPGW with a back-up ring attached. |