Technical Information

Defects and Countermeasures

O-ring

A summary table of common defects that occur when using O-rings and their corresponding countermeasures is provided for reference.

| Classification by failure | Phenomenon | Causes | Countermeasures |

|---|---|---|---|

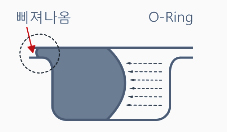

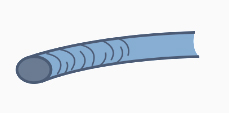

| Extrusion |

The O-ring extrudes from the groove due to high fluid pressure. |

1. The pressure is too high 2. The clearance is too large. 3. No back-up ring is used. |

1. Narrow the clearance. 2. Increase the rubber hardness. 3. Use a back-up ring. |

| Compression set |

The compressed section becomes permanently flattened. |

1. The temperature is too high. 2. A material with poor compression set resistance is used. 3. The O-ring was insufficiently vulcanized. |

1. Replace with a material that has good resistance to compression set. 2. Cool the seal area. |

| Hardening due to oxidation and heat |

The rubber hardens. Initially, it occurs on the surface and then progresses throughout the entire cross-section. A compression set accompanies it. |

1. The temperature is too high. 2. Crosslinking of the rubber material and evaporation of plasticizers. |

1.Select materials with good high-temperature properties and heat resistance. 2.Lower the operating temperature. 3. Prevent the surface from exposure to oxygen. |

| Extraction of plasticize |

The volume decreases. |

1. The temperature is too high. 2. Crosslinking of the rubber material and evaporation of the plasticizer. |

Use a rubber material with low plasticizer content or one that contains a plasticizer that is difficult to extract. |

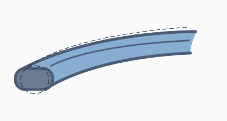

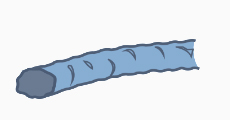

| Wear |

Linear wear occurs on the contact surface, parallel to the direction of motion. |

1. The mating surface is too rough or too smooth. 2. Poor lubrication. 3. High temperature and excessive dust. |

1. Properly finish the surface. 2. Improve lubrication. 3. Select a suitable rubber material. 4. Prevent dust intrusion. |

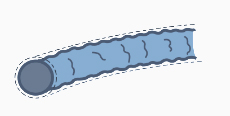

| Ozone cracks |

Numerous small cracks appear at right angles to the direction of the applied stress. |

Ozone attacks the double bonds in the rubber, causing it to break. |

1. eplace with ozone-resistant rubber material. 2. Protect the surface. |

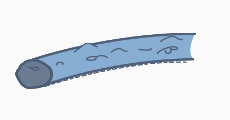

| Blistering (bubbles) |

Slightly cracked areas appear on the surface, and some parts may swell. |

High-pressure gas enters the rubber, and when it expands (as the pressure is released), it damages the rubber. |

1. Allow sufficient time when releasing pressure. 2. Use hard rubber or high-modulus rubber. 3. Use a compound formulated to resist blistering. |

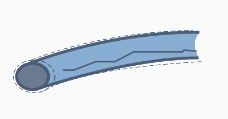

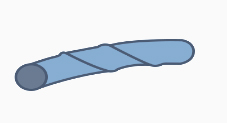

| Twisting |

Damage caused by twisting can be observed on the O-ring cross-section. |

1. One part of the O-ring is fixed, while another part bends and twists. 2. Uneven load. 3. Uneven lubrication |

1. Improve lubrication. 2. Narrow the clearance. |

| Twisting Damage due to improper installation |

A portion of the seal is shaved off, or part of the seal protrudes from the groove and is tightly pinched. |

1. Sharp edges or insufficient chamfering on the mating surface. 2. The seal is too small for the rod diameter. 3. The seal is too large for the piston diameter. |

1. Ensure proper chamfering and emove sharp edges. 2. Adjust the seal size to match the groove. |

| Abnormal wear on marked areas |

Only the marked area shows significant wear. |

The mark acts as a kind of foreign substance, causing localized wear. |

1. Do not apply marks. 2. Use a colored O-ring instead. |