CMP Equipment Parts

This key component is used in CMP (Chemical Mechanical Polishing) equipment during the polishing process of semiconductor wafers. It is attached to the back of the semiconductor wafer to hold or press the wafer. The company has succeeded in domestic production and is recognized for its advanced technology.

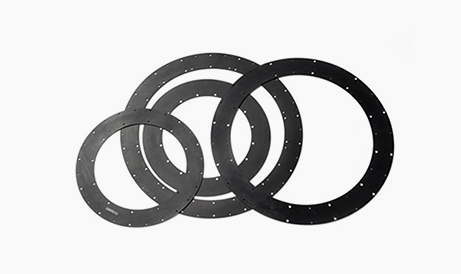

Membrane

Since this product comes into direct contact with the semiconductor wafer, it is characterized by having no defects such as scratches, foreign substances, or bubbles on the product. It is directly related to polishing, so the product thickness is controlled within ±0.1 mm across all areas.

Flexure

A gasket is installed inside the CMP equipment head to seal and prevent chemicals, such as slurry or impurities, from entering during polishing.

Air Bag

This part is used in air float-type CMP equipment and is mounted on top of the head to apply pressure to the wafer by inflating it with air.

Membranes are classified according to the head of each CMP equipment and are mainly produced in two sizes: 200 mm and 300 mm. As semiconductor chips have advanced toward higher integration and improved yield, the 300 mm size is primarily used. The 200 mm membranes are produced in two materials (EPDM and silicone), while the 300 mm membranes are produced solely from silicone.

300mm membrane

200mm membrane